Reverse Osmosis Pumps

High pressure desalination pumps

Reverse osmosis, also known as desalination, refers to the process whereby seawater is converted into fresh water for drinking, washing and other uses. The process uses a reverse osmosis pump to pump the seawater at high pressures through a membrane that removes the salt, minerals and other particles such as ions.

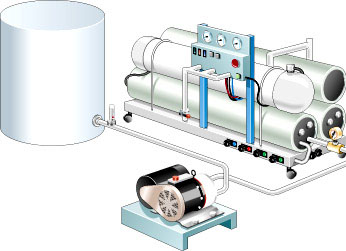

Due to the high pressures required from the desalination pump to force the seawater through the membrane, it is common for a multistage centrifugal, piston or side channel pump to be used. Some people therefore also refer to them as reverse osmosis booster pumps. On board a vessel where access to seawater is much greater than fresh water, desalination is a crucial application and therefore reverse osmosis water pumps need to be of a reliable and heavy duty design.

In the world of RO-desalination, the high pressure triplex plunger pump is an essential component and must be designed to handle these treacherous conditions.

In this reverse osmosis and desalination systems, high pressure plunger pump circulates the water, leaving extremely pure water, which is ideal potable water aboard yachts and ships away from the water molecules and expel clear water.

The significance of reverse osmosis over other methods for separation problems is a low energy requirement. The only energy needed is the pressure to force the fluid through the semi- permeable membrane. This is provided by a high pressure pump driven by electric motor or engine.

High pressure pump provides a smooth quiet continuous fluid delivery in offshore reverse osmosis (RO) installations and desalination systems.

PressureJet is a major supplier of corrosion resistant, stainless steel pumps for high pressure, seawater desalination, and reverse osmosis systems. Our complete line of SS 316, SS316L and Duplex Stainless Steel desalination pumps offer corrosion resistance, strength and long life, when pumping sea water under high pressure. We have many desalination pumps operating in systems on large ships, offshore platforms, island support and remote locations.

How Reverse Osmosis Booster Pumps Work

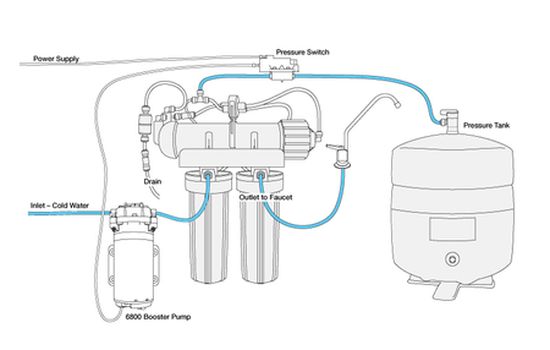

The purpose of the reverse osmosis booster pump is to increase water pressure going into the RO unit.

Reverse osmosis is a pressure-driven process. Small residential RO units will theoretically operate on very low pressure--down to 35 psi, according to some membrane makers--but the reality is, you won't get a lot of water and the product water quality will be compromised if the unit runs below 45 psi. Low inlet pressure makes the unit produce more reject water, produce less drinking water, fill the storage tank more slowly, and produce lower quality water.

RO units run well on typical city water pressure of 60 psi, but they run even better with a small pump to boost the pressure to 80 psi or higher.

The picture above shows the three essential elements of the RO booster pump. The white object at left is the transformer. It plugs into a standard wall outlet and converts to the voltage (most commonly 24 volts) required by the pump. The large object is the pump itself. The third device is the pressure switch. It monitors the water pressure in the RO unit's storage tank and turns the pump off and on in response to storage tank pressure. The most common shutoff pressure for undersink home RO units is 40 psi.

The standard pump setup is shown above. The function of the pressure switch in the tank line is to shut off current to the pump when the tank pressure reaches a preset level. Default pressure settings usually provide around 80 psi pressure going into the RO unit and shut off production when tank pressure reaches 40 psi. These settings can be adjusted, but it's usually best to leave them at factory setting. (Click the picture for a larger version.)

Do You Need a Booster Pump?

Most city water reverse osmosis users have enough city water pressure to run their RO unit nicely and they do not need a booster pump. For example, if your city water pressure is 60 psi or more, there is little to be gained by adding a booster pump. If your pressure is 50 psi or less, however, a pressure boost pump will give your RO unit more zip. You'll have more water, at a higher pressure, in the storage tank, and the tank will fill faster. The increased pressure will also improve the economy of the unit (it will run less reject water to drain) as well as the quality of the water. RO units thrive on pressure.